SOLUTIONS FOR FORMING & STAMPING MACHINES

沖壓及冷鍛成型的最佳解決方案

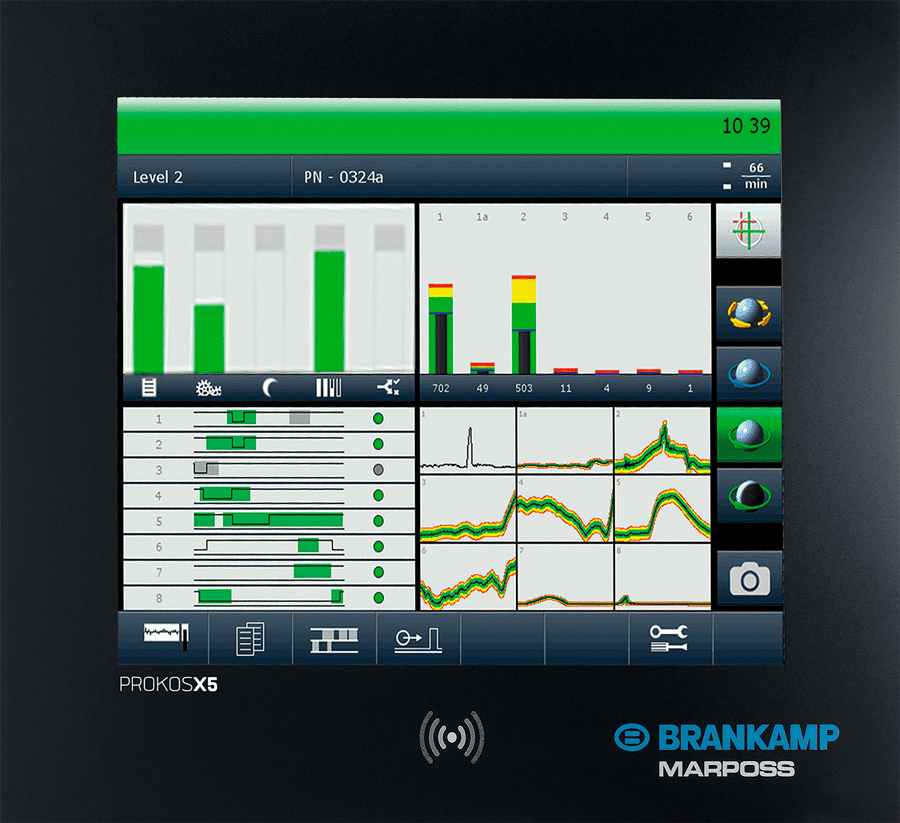

BRANKAMP is a global market leader of process monitoring, machine control and data collection, offering innovative technologies for in-process monitoring in the whole metal forming industry. Decades of experience in the cold forming-, stamping- and forging industry are embodied into the Marposs systems to improve productivity, part quality and reduce production costs.

Brankamp 是全球首屈一指的製程監控專家。在金屬成型的過程中,使用嶄新的技術能同時掌握機器設備即時狀況,並輸出生產數據。

Marposs 具備在冷鍛成型及沖壓產業數十年的經驗,能有效提升產品品質、改善效能,更降低生產成本。

OPTICAL GAUGING SYSTEMS

光學測量系統

Marposs Flexible Gauges are solutions designed for high precision controls of workpieces in the shop floor environment.

Comprehensive quality checks on parts are performed within a few seconds.

Thanks to the integration of optical and contact sensors into a single system, Marposs solutions offer an exceptional measuring capability

and guarantee that each specific measurement is always performed through the best technology and with the right acquisition strategy.

Marposs柔性量測系統是為在車間環境中對工件進行高精度控製而設計的解決方案。幾秒鐘內即可對零件進行全面的質量檢查。

由於將光學和接觸式傳感器集成到整套系統中,Marposs解決方案提供了卓越的測量能力,並確保始終通過最佳技術和正確的採集策略來執行每個特定的測量。

Measurement

Marposs introduces the I-Wave 2: the latest in manual

gauging

IN-PROCESS GAUGING

AND MONITORING ON

GRINDERS

磨床用製程中量測與監控

The need for increased efficiency in production cycles, an increasingly effective optimisation of the machining

times and an increase in

the demand of the quality

of parts produced, require

high performance measurement and control instruments for the grinding process.Marposs, the world leader

in this sector, offers solutions for every type of grinder.

為提高生產週期效率.優化加工時間提升效率,及提高所生產零件品質的要求,需要用於磨削過程的高性能測量和控制儀器。馬波斯(Marposs),該領域的全球領導者,為各式磨床提供解決方案。

Optoflash: the new measurement solution from Marposs

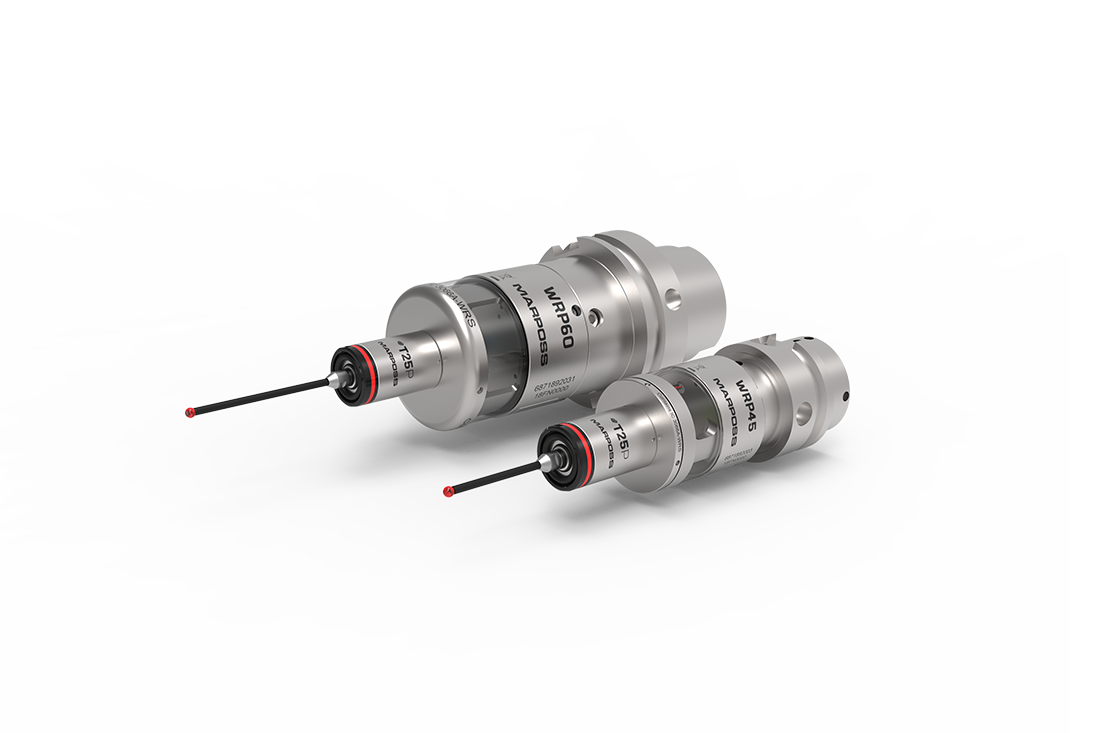

PROBING SOLUTIONS FOR CUTTING MACHINES

金屬加工機應用量測解決方案

For machining centers andmilling machines Marpossproposes many solutions for part inspection using:

• different wireless transmission technologies

• tool measurement and check systems with touch

and touchless techniques

• solutions for process monitoring through different types of sensors for checking

the status of

the tool and of the machine organs

• dimensional measurement onboard the machine by means of wireless measuring plugs mounted on the

spindle

• 對於加工中心和銑床,馬波斯提出了許多工件解決方案

• 多種不同的無線傳輸技術

• 具有接觸和非接觸技術的工件測量系統

• 通過不同類型的傳感器檢查製程狀態的過程監控解決方案

•安裝在主軸上, 通過無線測量測頭在機器上進行尺寸檢測

IN-PROCESS GAUGING

AND MONITORING ON

GRINDERS

磨床用製程中量測與監控

The need for increased efficiency in production cycles, an increasingly effective optimisation of the machining times and an increase in

the demand of the quality

of parts produced, require

high performance measurement and control instruments for the grinding process.Marposs, the world leader in this sector, offers solutions for every type of grinder.

為提高生產週期效率.優化加工時間提升效率,及提高所生產零件品質的要求,需要用於磨削過程的高性能測量和控制儀器。馬波斯(Marposs),該領域的全球領導者,為各式磨床提供解決方案。

P1D ME

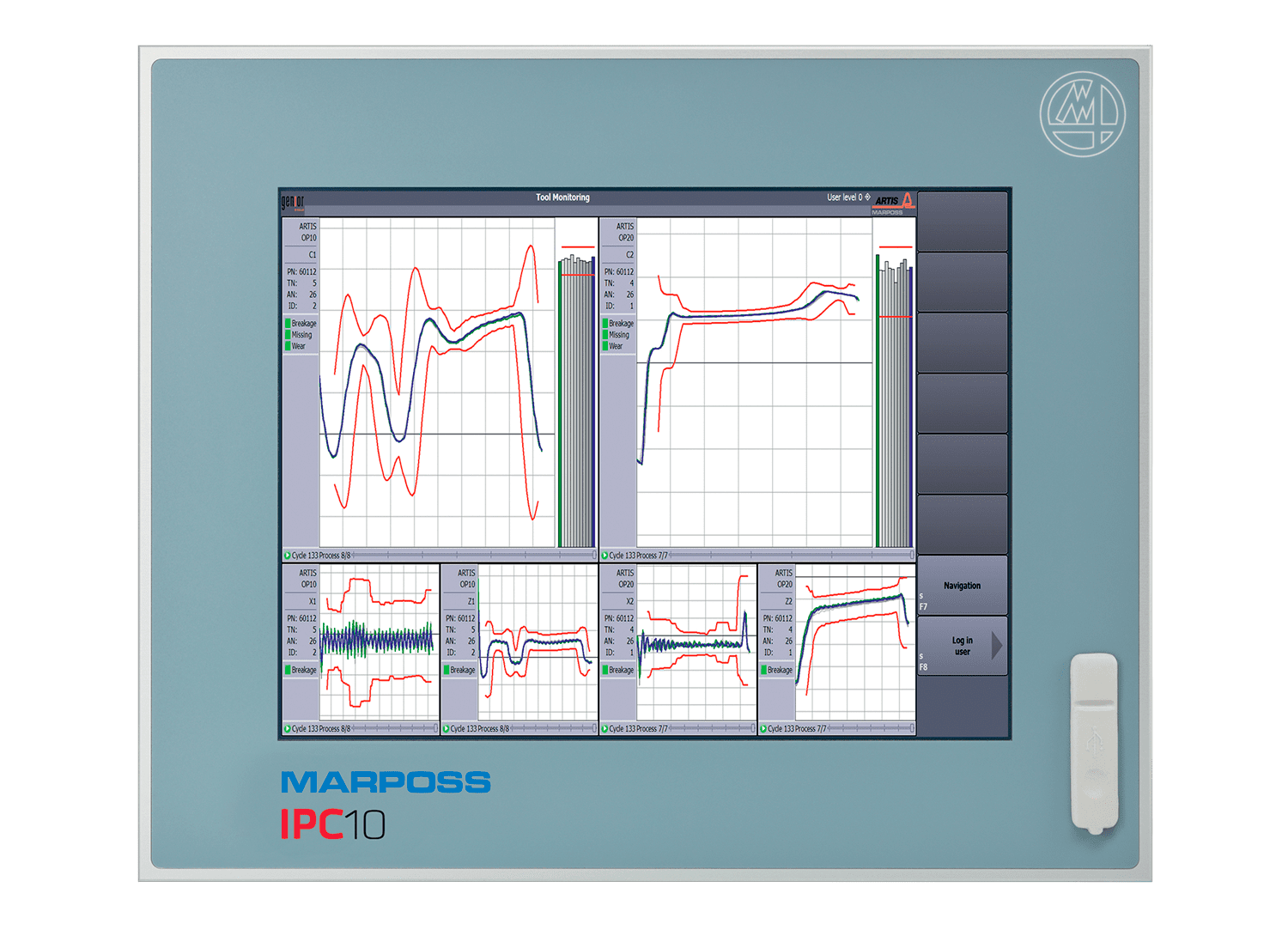

Genior Modular: Process Monitoring for Cutting Machines

Marposs TTV Total Thermal Vision

SOLUTIONS FOR TOOL AND PROCESS MONITORING

刀具和過程監控系統解決方案

Artis tool and process monitoring systems capture the condition of the tool throughout the machining process. The systems provide individually adjustable signal limits to detect e.g. wear of the cutting edge and tool fracture. Cutting tools are loaded with heavy forces at the deformation and friction zones.Tool wear often leads to quality problems. can damage follow-on tools, work pieces or spindles.Since machines today often work unattended and 24/7, permanent monitoring of the tool condition is required.

When using Artis systems, it is possible to stop the machine in time if a tool breaks in order to avoid further damage to the tool used in the next operation.

Additionally, an immediate stop of the machine axis in the event of tool breakages prevents collisions.

Artis刀具過程監控系統可在整個加工過程中擷取刀具的製程狀態。

系統提供可單獨調節的信號極限,以檢測如切削刃的磨損和刀具斷裂。切削刀具在變形和摩擦區域承受很大的壓力。

刀具磨耗通常會導致質量問題,而磨耗又會損壞後續的刀具,工件或主軸。由於當今的機器通常無人值守和全天候工作,因此需要對刀具狀態進行永久監控。

使用Artis系統時,如果刀具損壞,可及時停止機器,以避免進一步損壞下一次操作中使用的刀具。

在刀具破損情況下,機床軸立即停止可防止碰撞。

Company Intro

Marposs Group.mp4

DIAMOND Line: the high precision product range

Marposs

Experience Marposs Innovative Solutions for E-Mobility.mp4

MISSION

Marposs mission is to provide precision metrology equipment for use in the workshop environment during and after machining operations.

The equipment is designed and built for a wide range of in-process and post-process applications and for guaranteed performance in even the harshest shop floor conditions.

Marposs provides a global answer to customers needs, supplying the metrology equipment in association with non-destructive testing and a wide variety of sensors and machine tool controls.

Marposs products are offered as a part of a complete project management and simultaneous engineering support to the customer.

Marposs has become a world leader in measurement technology by offering its customers a combination of advanced products, market knowledge and commitment to long term global partnerships. Building on these foundations, Marposs has created an international organization able to deliver application, design and service support virtually anywhere in the world.

P1DME,e-Actuators: e-Slide and e-Fenar

GAUGING COMPONENTS,COMPUTERS & SPC

量規組件, 電腦與統計製程管理

Components provided are:

• Probes and measurement transmission elements:

mechanical components

and sensors

• Indicators and display units: mechanical and electronic units to elaborate and display results

• Signal converters: to convert sensor values betweendevices

• Data acquisition systems: interface units to connect analog and digital sensors to an industrial PC

• Industrial Computers (embedded computers, panel

PC and workstations)for data processing and control

• Application software to create distributed shop-floor

data acquisition systems

for Statistical Process andQuality control (SPC).

提供的組件有:

• 探頭和測量傳輸元件:機械零件和傳感器

• 指示器和顯示主機:機械和電子元件,用於統計和顯示結果

•信號轉換器:在設備之間轉換傳感數值。

•數據採集系統:用於將模擬和數字傳感器連接到工業PC的接口單元。

• 工業電腦(嵌入式計算面板PC和工作站)用於數據處理和控制。

•應用軟體創建分佈式車間

用於統計過程和質量控制(SPC)的數據採集系統。

LASER SENSORS & SYSTEMS FOR DIAMETER CONTROL

用於直徑控制的雷射測徑儀設備

AEROEL by Marposs designs and manufactures high accuracy Laser Micrometers and Laser Gauges for non-contact diameter measurement and control. Suitable for on-line or off-line application, to check a number of different products, to improve process efficiency by reducing scrap and manpower, to assure dimensional consistency and product quality.

The SUPER-MECLAB+.X Bench Top Laser Micrometer, for example, is a high precision instrument for ultra-high accuracy diameter measurements. It is ideal for the off-line, manual measurements of a wide range of ground or turned parts with different shapes and sizes,such as electric motor shafts, ground or turned parts, gag pin, piston pins, hydraulic components.

Marposs的AEROEL設計和製造是應用於非接觸式直徑測量和控制的高精度雷射測徑儀。適用於在線或離線應用,以檢查多種不同的產品,通過減少廢品和減少人力來提高工藝效率,確保尺寸一致性和產品質量。

SUPER-MECLAB + .X雷測測徑儀是用於超高精度直徑測量的高精度儀器。

它是離線,手動測量各種形狀和尺寸不同的研磨或車削零件的理想選擇,例如電動馬達軸承,研磨或車床完成的零件,量規插銷,活塞插銷,液壓機購元件。

PROBING SOLUTIONS FORCUTTING MACHINES

金屬加工機應用量測解決方案

For machining centers andmilling machines Marpossproposes many solutions for part inspection using:

• different wireless transmission technologies

• tool measurement and check systems with touch and touchless techniques

• solutions for process monitoring through different types of sensors for checking

the status of the tool and of the machine organs

• dimensional measurement onboard the machine by

means of wireless measuring plugs mounted on the spindle

• 對於加工中心和銑床,馬波斯提出了許多工件解決方案

• 多種不同的無線傳輸技術

• 具有接觸和非接觸技術的工件測量系統

• 通過不同類型的傳感器檢查製程狀態的過程監控解決方案

•安裝在主軸上, 通過無線測量測頭在機器上進行尺寸檢測

MONITORING SOLUTIONS FOR LIGHT ALLOY DIE CASTING PROCESSES

輕合金壓鑄過程的監控解決方案

Aluminium plays a decisive role in the automotive sector, where weight reduction, and therefore cost savings, are paramount.

Over the last decade, there has been a demand for increased performance in die casting processes to achieve a defect-free large scale production. This is why any faults or imperfections in the finished product become highly critical and need to be eliminated.

Total Thermal Vision control system allows foundries to achieve greater efficiency of the casting process, by monitoring the surface

temperature of the dies with infrared vision. Marposs is the ideal partner for foundries thanks to its many years of experience in monitoring processes in the most hostile and aggressive

industrial environments.

鋁在汽車領域起著決定性的作用,在汽車領域,減輕重量以及降低成本至關重要。 在過去的十年中,一直需要提高壓鑄工藝的性能以實現無缺陷的大規模生產。 這就是為什麼成品中的任何缺陷或瑕疵變得非常關鍵並需要消除的原因。

熱像圖過程控制系統通過使用紅外視覺監控模具的表面溫度,使鑄造廠能夠提高鑄造工藝的效率。憑藉以下優勢,Marposs是鑄造廠的理想合作夥伴。

Marposs Monitoring Solutionsfor Stamping Machines

MARPOSS LINE