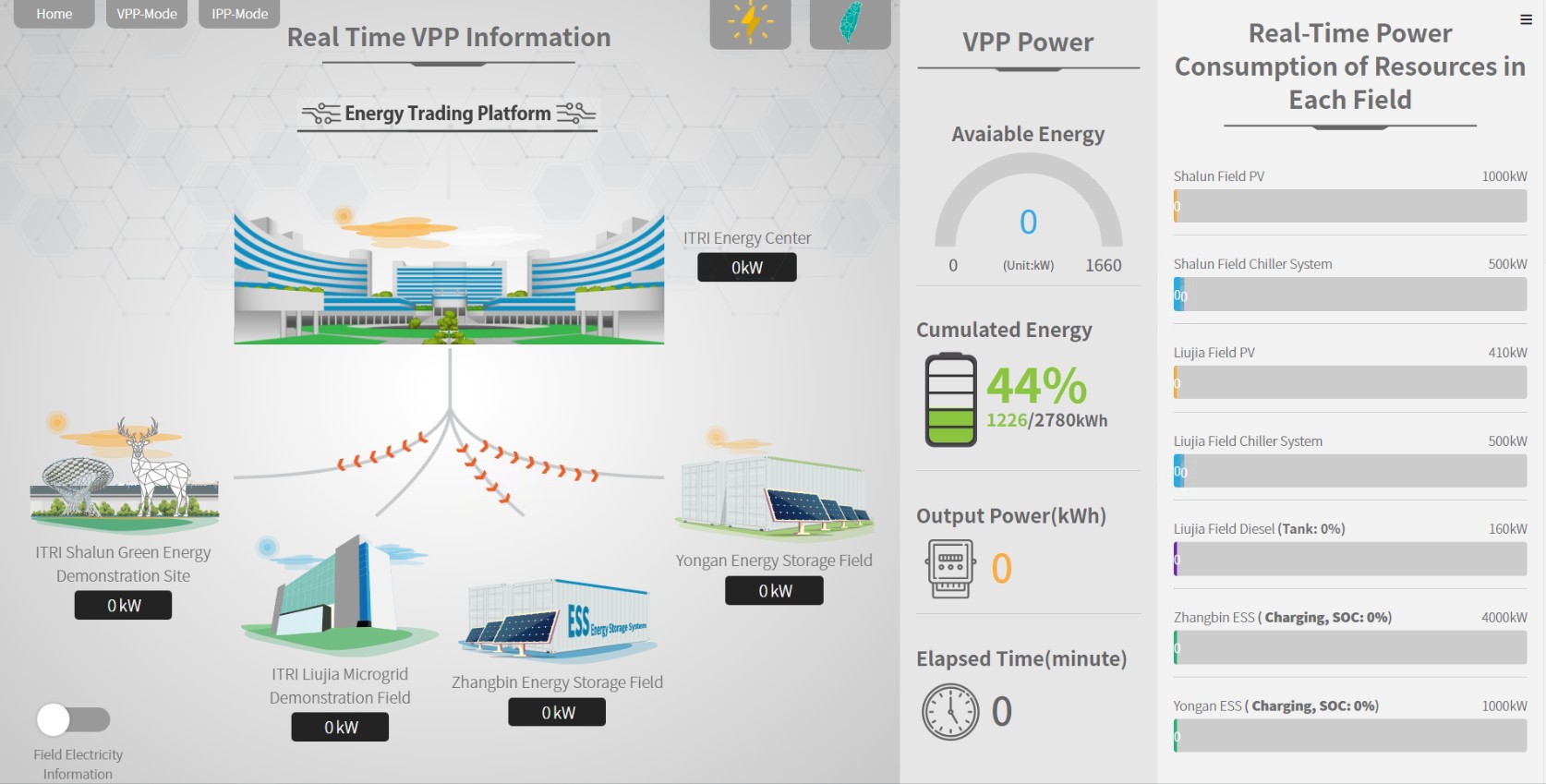

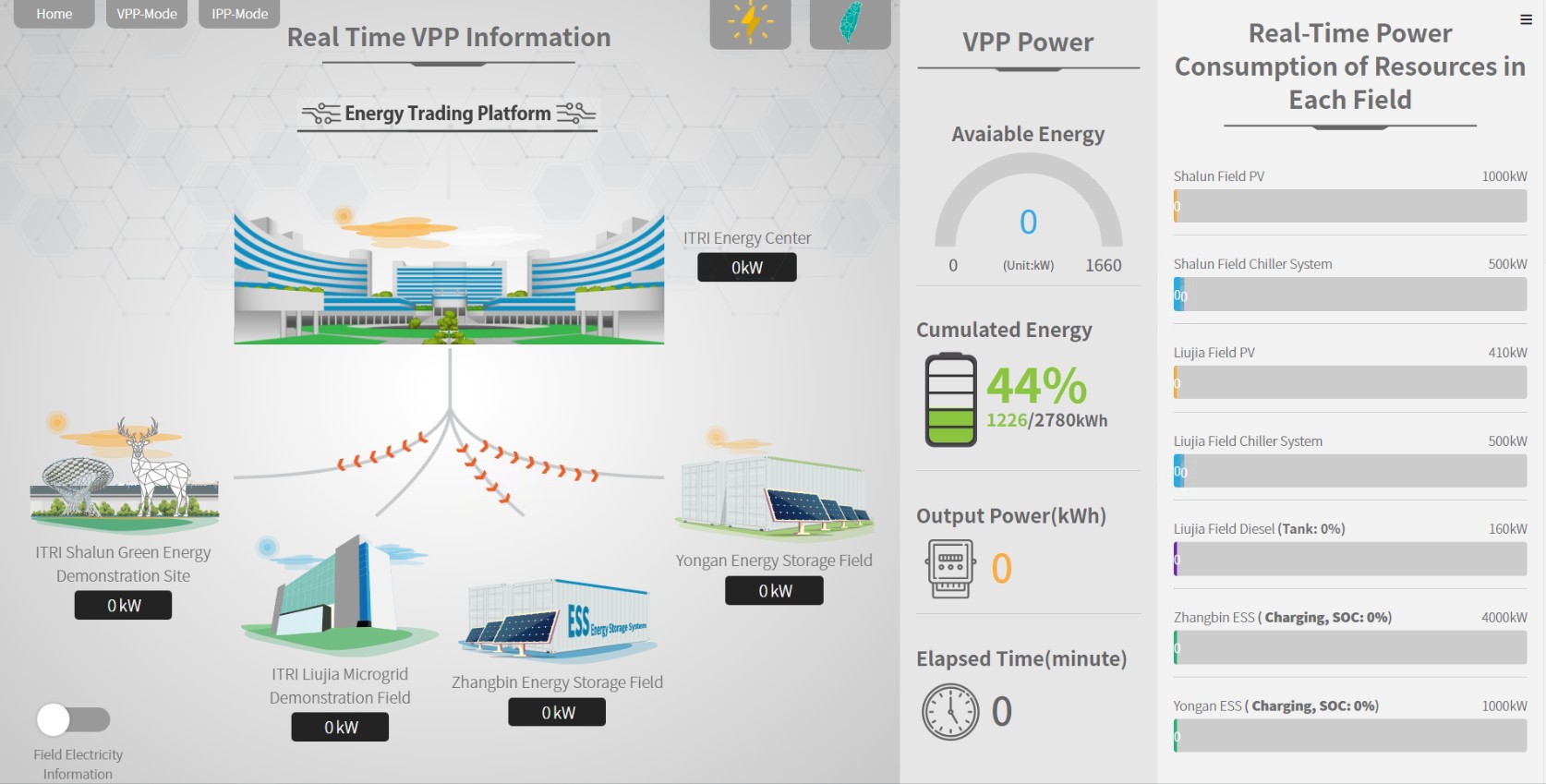

VPP Technology Verification Platform with Aggregation of Distributed Resources

To achieve the goal of net-zero carbon emissions, flexible renewable energy accommodation is necessary for electrical grids. By introducing Virtual Power Plant (VPP) technology, existing private resources can be properly utilized to improve the stability of the electrical grid. The VPP technology is based on AI algorithms and the plug-and-play remote unit U-Box. It can aggregate DERs (distributed energy resources) scattered throughout different regions to provide ancillary services in the electricity market.

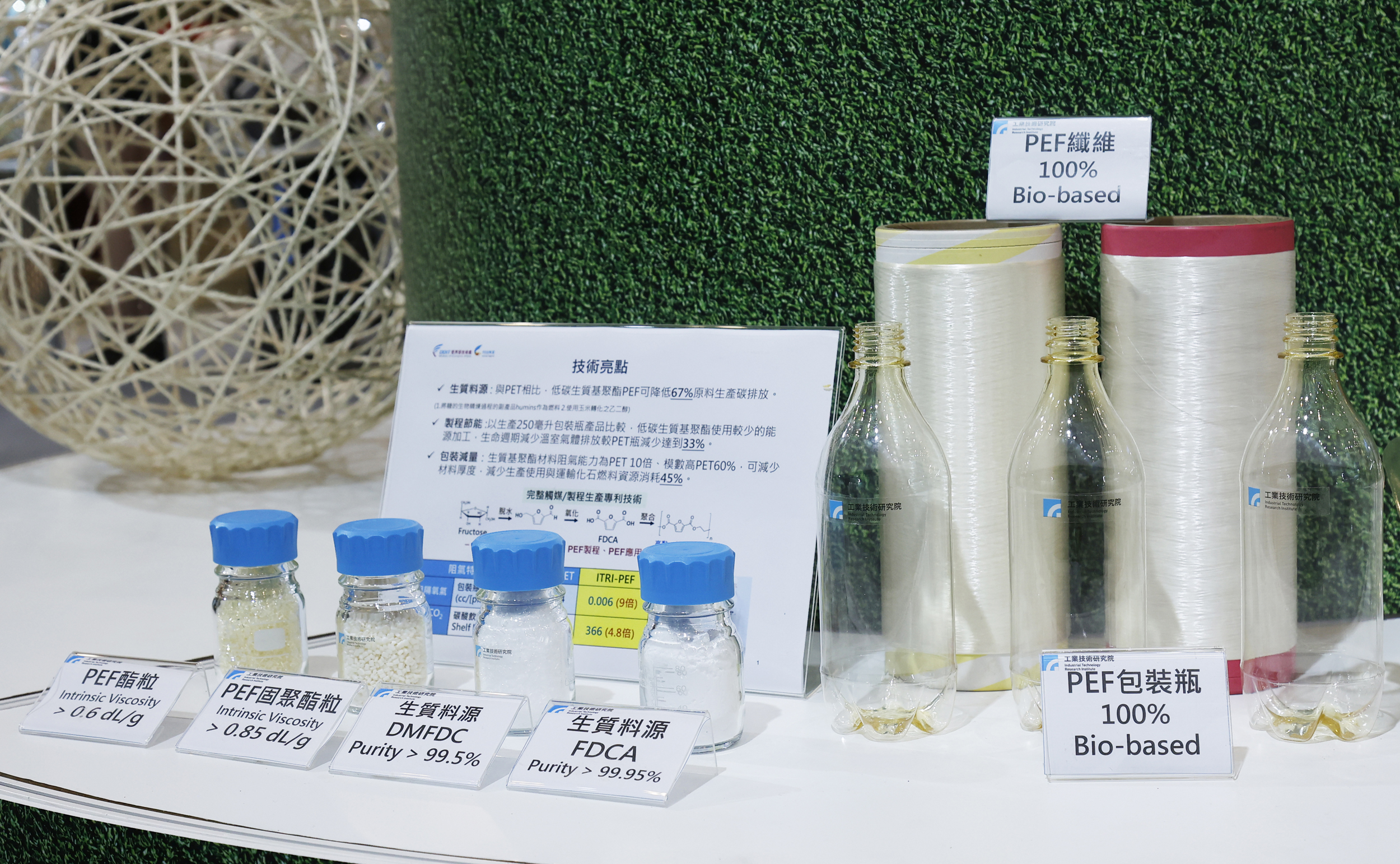

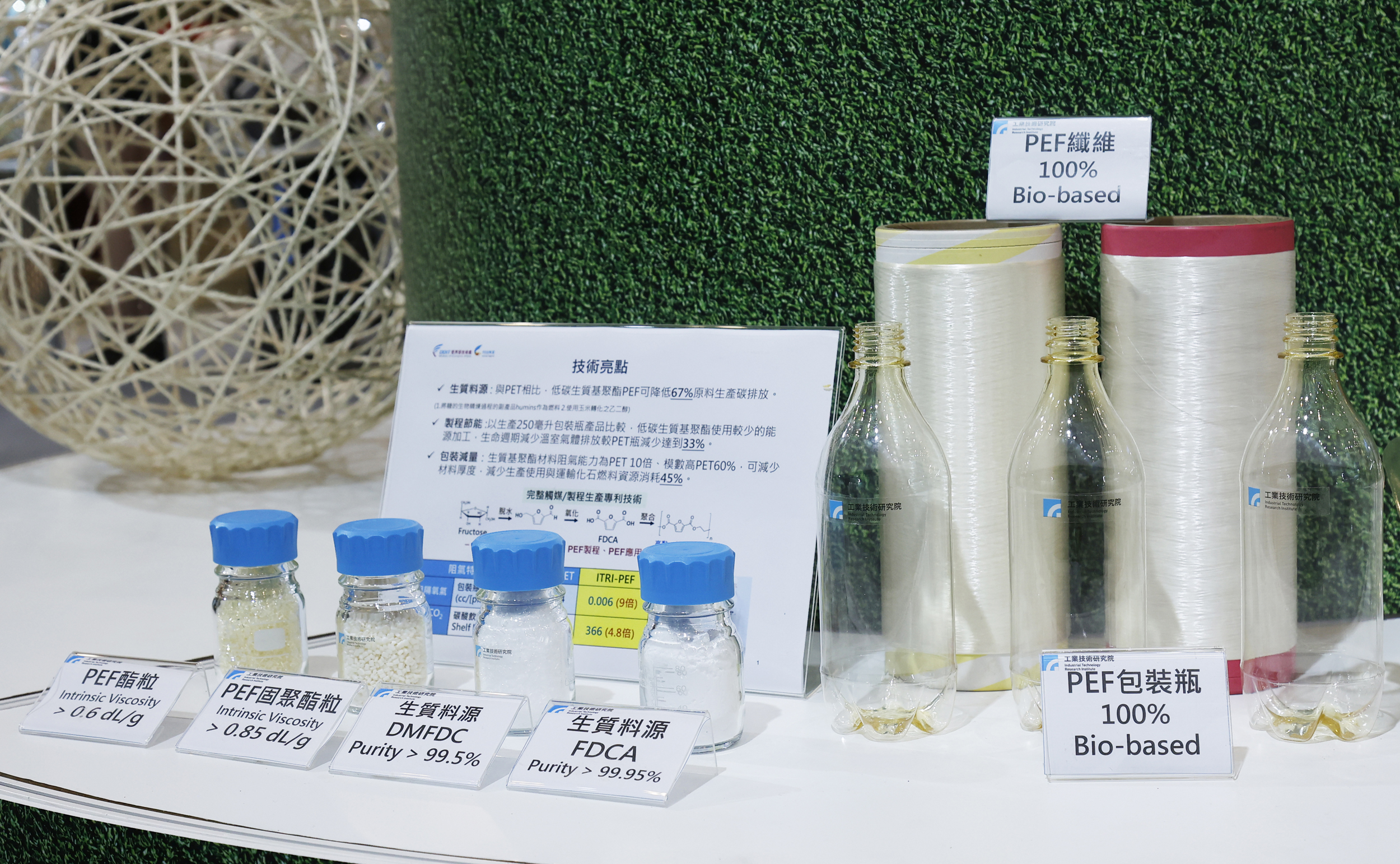

Low Carbon 100% Bio-Based PEF Polyester Material

ITRI has developed a biomass conversion catalyst and polymerization technologies to produce 100% bio-based polyethylene furanoate (PEF) to replace petrochemical-derived polyethylene terephthalate (PET). The new generation PEF has excellent processing characteristics: better oxygen barrier capacity and stronger mechanical properties. It can produce lighter, thinner, but stronger bottles or food packaging materials, reducing greenhouse gas emission during production by 67%.

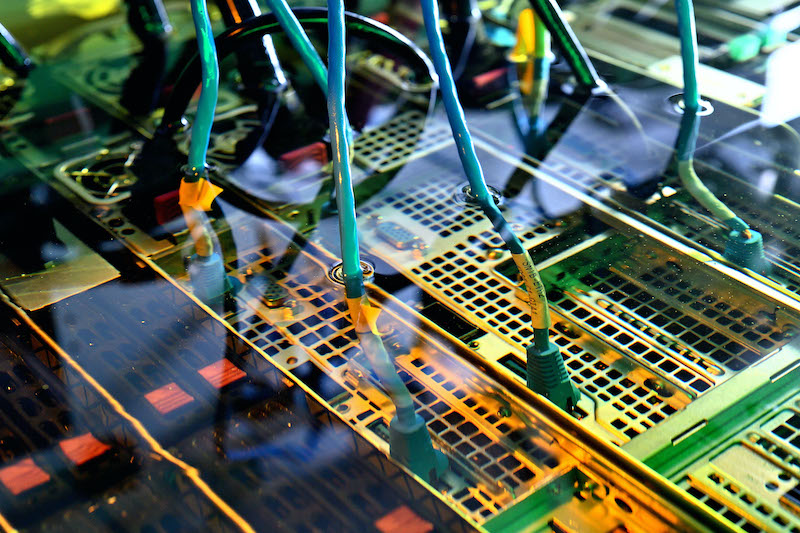

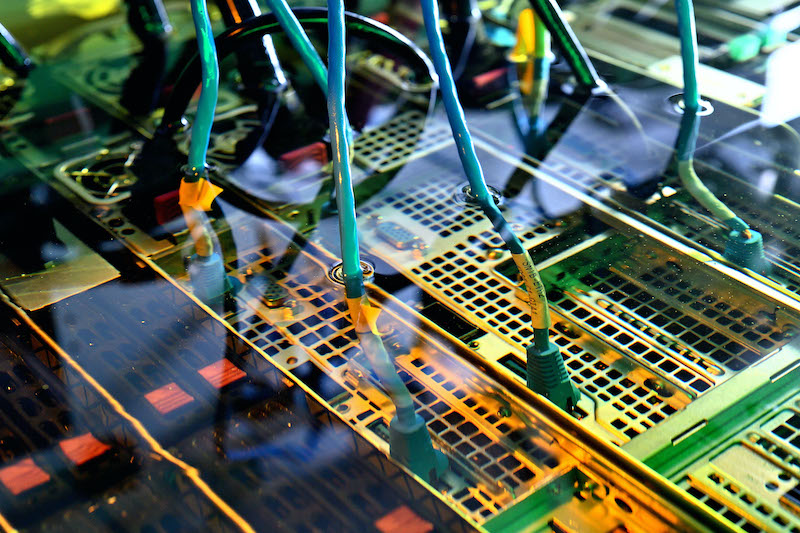

Micro Immersion Cooling Data Center

Amid the surging demand for cloud computation in the 5G era, the reliability and energy consumption of data centers are crucial to cloud service providers which look to achieve net zero emissions. ITRI developed a green data center and an energy-efficient micro immersion data server. With passive cooling and remote management technologies, the size and energy consumption of computing equipment can be reduced. These efforts will also facilitate high-reliability edge computing applications.

Networked Amide Epoxy Polymer Electrolyte for Solid State Lithium-Ion Batteries, NAEPE

Cloud Carbon Management Platform

The cloud carbon management platform is built based on ITRI’s over 20 years of experience in life cycle assessment and industry consulting. Its database includes more than 10,000 entries covering nearly 20 industry sectors in Taiwan. The platform guides users to check and calculate carbon footprints and generates analytical reports. It also provides carbon reduction comparison to assist manufacturers in determining raw material replacement, enabling them to move towards low-carbon design and production.

Building Energy Simulation Technology & Analysis Platform

Networked Amide Epoxy Polymer Electrolyte for Solid State Lithium-Ion Batteries, NAEPE

NAEPE is a nonflammable, low-cost solid-state electrolyte with high ionic conductivity and voltage stability. It is a key material for the next generation solid-state Li-batteries, offering high energy density cells with better safety and cycle life. NAEPE is suitable for applications that operate at high voltages and temperatures.

Total Solution for LCD Panel Recycling

ITRI has developed a total solution for LCD panel recycling, turning waste into valuables with a cost-effective six-step process. With the techniques such as separation, extraction, purification, scrubbing, concentration, and modification, the process enables the reuse of the waste LCD panel components. Liquid crystal, indium, and glass are then made to new LCDs or liquid crystal smart windows, indium targets, green construction materials and multifunctional adsorbents, respectively. This also presents an example of creating a circular economy.

Building Energy Simulation Technology & Analysis Platform

Building Energy Simulation Technology & Analysis Platform can quickly perform an analysis via standard building models developed with diverse building types. It also has a complete database of construction materials and equipment, in which reliable internet resources and data can be searched on a regular basis using web crawler technology with artificial intelligence. It's intelligent screening and sequencing technologies for equipment are used to provide a list of optimal equipment, as well as an assessment and recommendations on energy conservation and economic benefits, in order to both diagnose the energy consumption problems within current buildings and propose solutions.

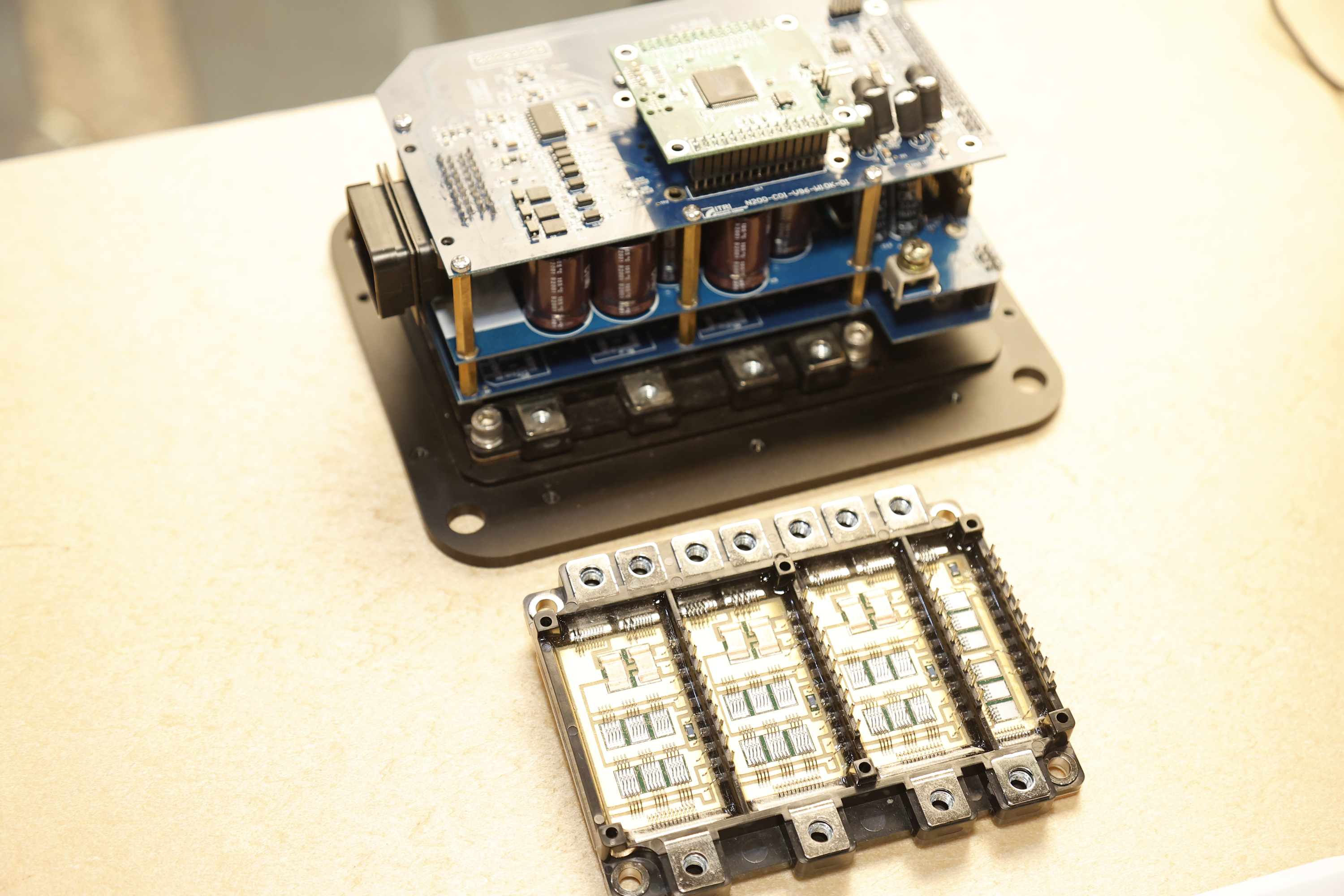

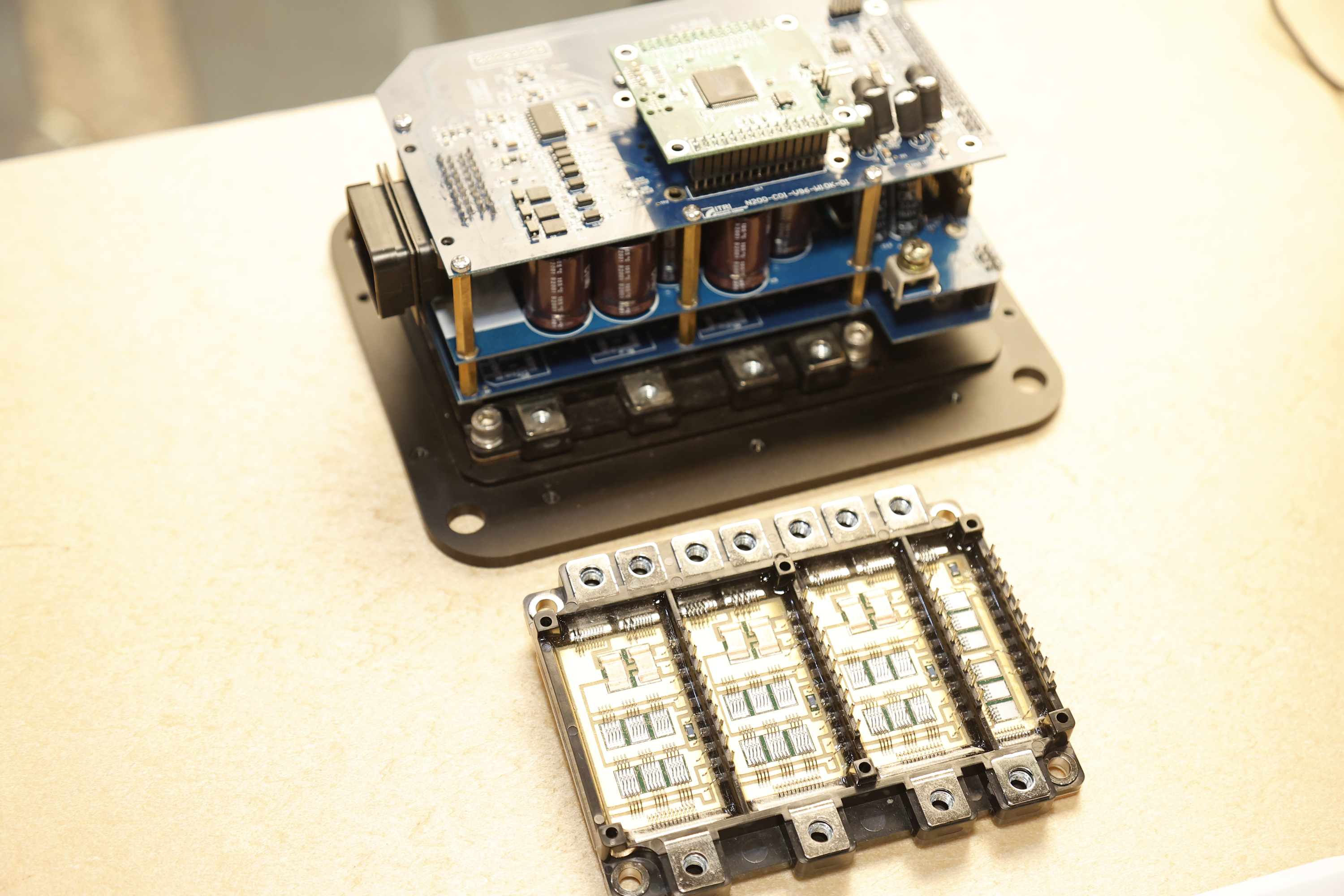

E-scooter Motor Drive

This e-scooter motor drive incorporates the world’s first high power density e-scooter PIM with more than 8kW power. The PIM developed by ITRI’s power electronics research group, combines three-phase inverter and DC converter, current inductance, protection switching, and temperature sensing. The utilization of high-density system-in-package (SiP) further increases the power density by three times than that of the discrete module. Furthermore, the use of insulated metal substrate makes the power module more reliable and safer. The flexible module integrates with the motor drive and penetrates the AM market easily due to its easy-to-change characteristic that can significantly reduce the motor malfunction frequency.

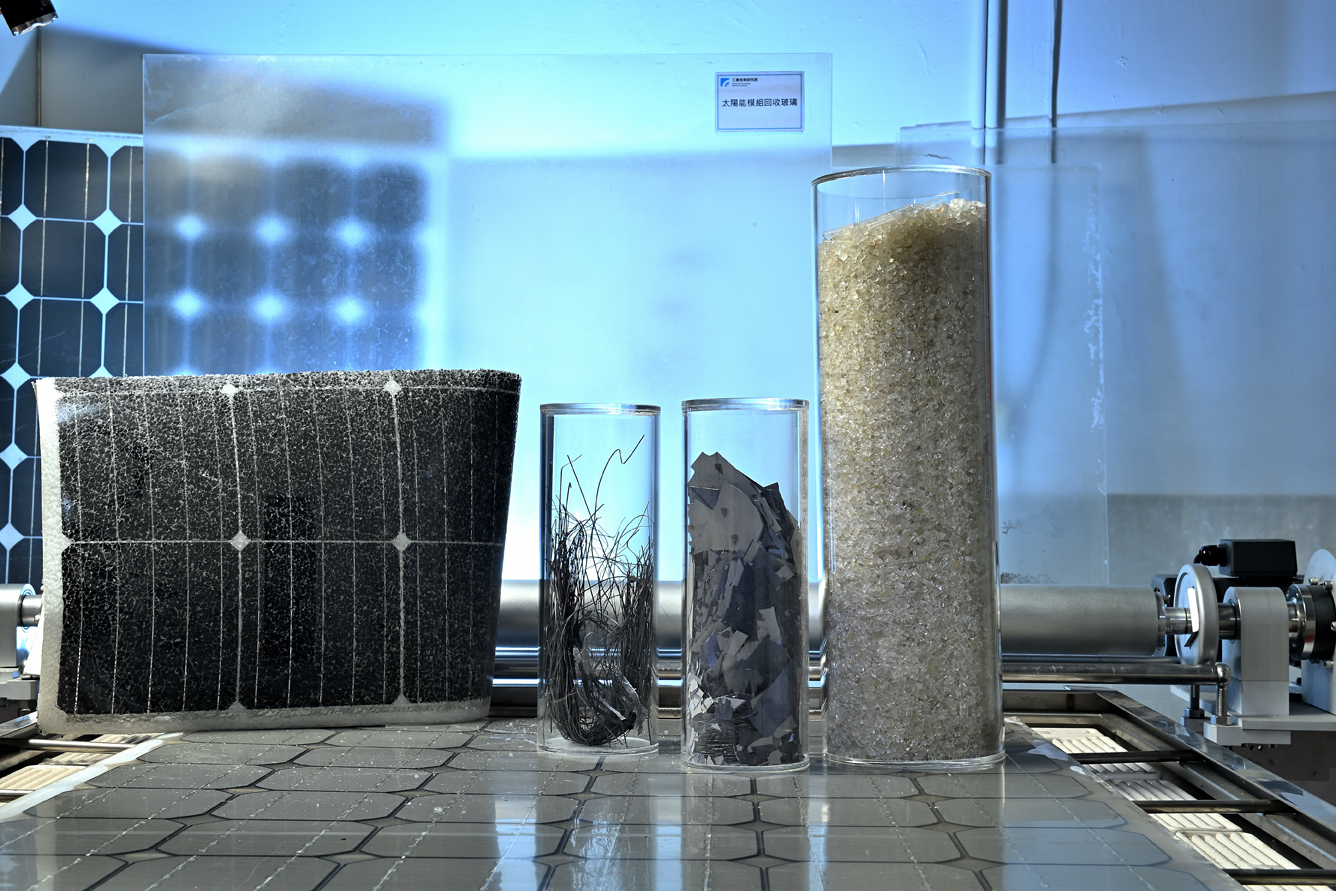

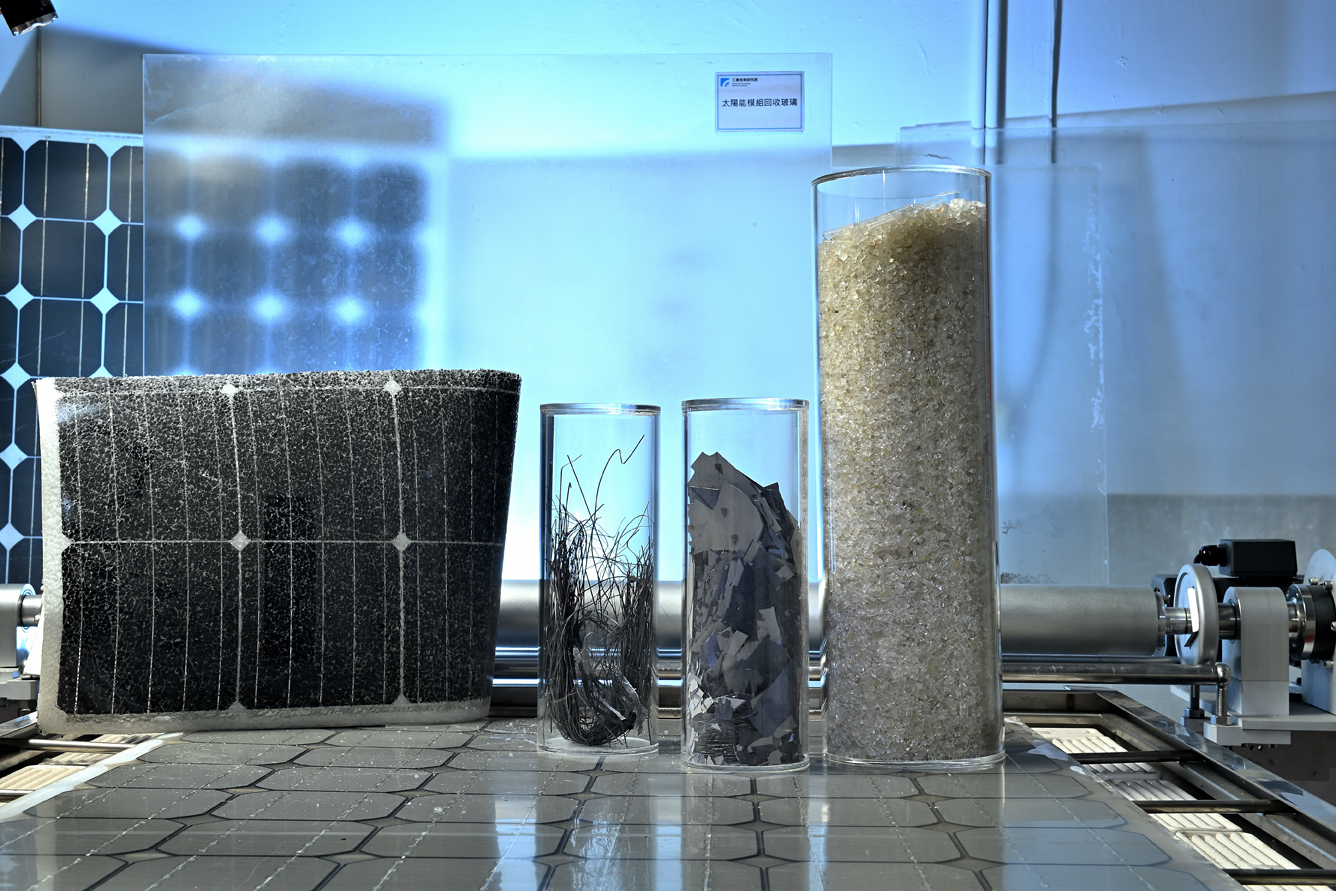

Easy Disassemble PV Module Technology

Easy Disassemble PV Module Technology

Traditional PV modules featuring product longevity are difficult to disassemble and have a low recycle value. To address this issue, ITRI developed a new design that makes module disassembly easy and keeps the cells intact. The dismantled components and materials can be recycled and reused, creating new values for PV modules and achieving environmental sustainability.